Xerox Touts 3D Liquid-Metal Printing for Manufacturing

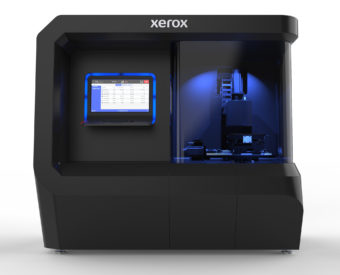

Xerox prototype of its 3D printer that uses liquid metal to create manufacturing parts.

Xerox recently posted a blog entry describing how it aims to take its 3D liquid-metal printing technology to market next year, with the technology designed for advanced 3D-printing manufacturing applications.

According to Xerox Chief Technology Officer, Naresh Shanker, Xerox has been testing its 3D printing with the U.S. Department of Defense and NASA “to design some of the most complex parts in the world.”

“3D printing is going to transform manufacturing, and Xerox is going to drive that change,” said Shanker.

Xerox notes that 3D printing has been around for years, used for rapid prototyping, modeling, and in education. According to Forrester VP, Carlton Doty, writing in an October 2018 research report, what’s changed is: “The costs have plummeted, the capabilities of the hardware and software are advancing exponentially, and innovations in materials science now enable manufacturers to print end-use components at scale with the quality standards they demand.”

Xerox aims to disrupt traditional manufacturing through its 3D liquid-metal technology combined with AI-based design software. “By pairing these two technologies, manufacturers will be able to design and fabricate parts that meet their structural and cost requirements on the first try,” said Shanker.

The company says that to meet business needs for on-demand products, Xerox 3D printing technology uses liquid metal printing to decrease production time from days to hours. Xerox 3D metal printers also use off-the-shelf alloys—the same alloys used in traditional manufacturing, allowing manufacturers to design parts using materials they already know. This means parts are denser, faster to make, and less expensive than those made with metal powders.

That means that, thanks to on-demand printing, companies will no longer have to buy parts on a decades-long timeline. For example, if a customer orders an airplane that lasts for 30 years, they also need to purchase hundreds, if not thousands, of spare parts. “You would have to pay to store these spare parts,” says Dr. Bryony Core, senior technology analyst at IDTechEx. “This leads to a waste of time, money, and effort.” As with 2D printing on paper – on-demand 3D printing can significantly reduce inventory and storage costs.

Xerox’s AI-based 3D software is said to integrate all steps of fabrication from design to manufacturing planning and performance analysis, allowing for consistent part quality and customization.

An item printed by Xerox using liquid metal technology.

“Using 3D printing to make unusual geometric parts out of lightweight materials, like high performance polymers, or composite materials, means you can offer an improved product,” says Core. In the auto industry, for instance, the technology can allow car makers to replace traditional parts with lighter-weight versions and reduce vehicle weight. That can substantially lower fuel costs and carbon emissions over the lifetime of a car.

“We are about to enter the most disruptive era in manufacturing since the Industrial Revolution, thanks to additive manufacturing,” concluded Doty.

Our Take

Xerox is somewhat late to the 3D-printer manufacturing/industrial party, and will have to contend with established players, ranked in order of market share: Stratasys, 3D Systems, EnvisionTEC, EOS, Carbon and HP Inc. (both tied for fifth place). As we know, Xerox is currently trying to purchase HP. If it does succeed in acquiring HP, it would likely mean a huge boost to its fledgling 3D-printer business.

More Resources

You must be logged in to post a comment.