Lexmark Collected 7,634 Metric Tons of Returned Toner Cartridges Last Year

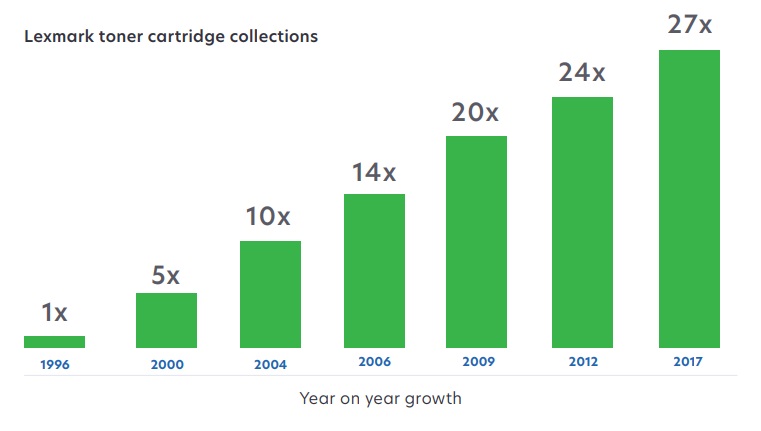

In its just-released 2017 Corporate Social Responsibility Report, Lexmark International reported on a number of its key environmental and social achievements, including that, under the Lexmark Cartridge Collection Program (LCCP), Lexmark collected 7,634 metric tons of returned toner cartridges from its customers in 2017. Along with this, 97-percent of materials reclaimed from these cartridges were reused or recycled. Altogether, more than 40 percent of total Lexmark toner cartridges shipped worldwide last year were returned through the LCCP

Under the LCCP, once customers receive a new Lexmark toner cartridge, they simply package their depleted toner cartridge in the provided packaging and ship it back to Lexmark for recycling free-of-charge with a Lexmark-provided pre-paid label.

Toner cartridges returned to Lexmark’s manufacturing facilities LCCP are disassembled, and then components suitable for reuse are selected and used in the production of Lexmark Corporate Cartridges.

Lexmark recovers post-consumer recycled (PCR) plastic from empty toner cartridges and pelletizes the PCR for integration into new parts. Reclaimed PCR plastic is incorporated into 40 Lexmark components at a level of up to 100 percent PCR plastic.

Lexmark’s goal is to increase the cartridge material reused through its collection program to 50 percent (by weight) by 2018.

Reclaimed Plastic

Lexmark says it’s an industry leader in the use of reclaimed plastic, with 18-percent average PCR plastic content, by weight, across all new Lexmark-branded toner cartridges. One of the company’s goals is to increase the post-consumer recycled plastic content in its toner cartridges to 25 percent by 2018. Altogether, 91 percent of Lexmark-designed and manufactured toner cartridges contain at least some post-consumer recycled plastic content.

Long-Life Imaging Components

Lexmark also stresses that it not only provides key recycling of its products, but also provides long-lasting products. Its long-life imaging components, which can last up to 150,000 pages depending on customer usage, minimize the need to replace parts.

An ultra-durable coating used in the Lexmark photoconductor unit is said to provide excellent print quality throughout its extended life. Toner-cartridge design improvements are also said to reduce toner waste by up to 50 percent over Lexmark’s previous product generation, resulting in higher efficiency and yield. An automatic color-retract feature also pulls color-printing components away during monochrome printing to prevent unnecessary wear. All of this helps save resources, reduces waste, and require less maintenance.

Lexmark also notes that over 90 percent of the materials used in its hardware products by weight are recyclable. The majority of these materials are polymers and metals that are formed into components through injection molding or stamping operations.

See the complete Lexmark 2017 Corporate Social Responsibility Report here.

More Resources

- June 2018: With New A4 Lineup, Lexmark Completes 92-Percent Refresh of Hardware Lineup

- May 2018: Lexmark Printers, Copier/MFPs Achieve Hardcopy Common Criteria Certification

- May 2018: Lexmark VP Discusses Lexmark’s Biggest Product Launch Ever, Channel Strategy

- April 2018: Lexmark Focuses on Faster Print and Scan Speeds, Higher Toner Yields, and More with New A4 Models

- April 2018: Ringdale’s FollowMe Embedded Available for Lexmark’s Latest A4 Printers and Copier/MFPs

- March 2018: New Lexmark Pharmacy Order Assistant Minimizes Outdated Fax Communications

- January 2018: New Lexmark MFP Kiosk for Government Provides Document-Capture, Print-on-Demand, Forms Repository

- December 2017: Lexmark’s New Patient Communication Solution Provides Color Printing, Print-on-Demand for Healthcare

- December 2017: Lexmark Introduces RFID Laser Printing for Manufacturing

- November 2017: New Lexmark Advanced Output Management for Healthcare Eliminates Printer-Downtime Backups

You must be logged in to post a comment.