Kodak and Carbon 3D to Jointly Develop 3D-Printing Technology

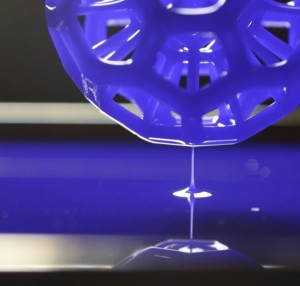

Carbon’s Continuous Liquid Interface Production (CLIP) technology for 3D printing

On March 11th, Eastman Kodak announced that it had signed a joint development agreement with Carbon3D to work together on new opportunities for Carbon’s Continuous Liquid Interface Production (CLIP) technology for 3D printing.

According to Kodak, CLIP eliminates the shortcomings of conventional 3D printing by using a tunable, photochemical process to “rapidly transform” 3D models into physical objects. CLIP works by balancing the interaction of light and oxygen to grow parts with “excellent mechanical properties, resolution, and surface finish.” CLIP is said to be 25 to 100 times faster than conventional 3D printing – producing a particular object in just about six minutes, compared to 3 hours for polyjet 3D printing, 3.5 hours for SLS printing, and 11.5 hours for SLA 3D printing.

The joint development agreement aligns Carbon’s material-development capabilities with Kodak’s standing experience in material-formulation and integration into complex systems.

Dr. Joseph DeSimone, CEO and Co-Founder of Carbon commented: “This collaboration further proves our dedication to the development of breakthrough additive materials.”

“Together, Carbon and Kodak are well positioned to develop and expand market opportunities for CLIP-based additive manufacturing,” said Kodak CEO Jeff Clarke. “Kodak is a world leader in materials development and we are excited to be working with an innovative and progressive company like Carbon.”

More Resources

- January 2016: IDC: Global Spending on 3D Printing Will Grow at 27 Percent CAGR

- January 2016: IDC: China to Surpass U.S. with 3D-Printer Shipments this Year

- December 2015: Global 3D-Printer Market has Hit Half-a-Million Shipments, but Market Struggling Lately

- October 2015: U.S. 3D-Printer Market is ‘White Hot,’ According to New Research from IDC

- September 2015: Gartner Forecasts that Almost Half-a-Million 3D Printers Will Ship in 2016

- March 2015: Carbon3D’s 3D Printing Said to be up to 100-Times Faster than Conventional 3D Printing

- July 2015: Global Shipments of 3D Printers More than Double in First-Quarter 2015

You must be logged in to post a comment.